Focused on People-Centred Design

In collaboration with Atlas Copco

10-week Personal Project

10. 2018 - 01. 2019

_ Next Generation in Aerospace Assembly

“Next Generation Aerospace Assembly” was the project to collaborate closely with AtlasCopco in exploring the future in the industry of aerospace assembly and getting new insights via addressing relevant problems and design opportunities.

CONTEXT | Wing box Introduction

The structure of the aircraft wing is rather special and complex compared to other parts of the aeroplane. In large passenger aircraft, a large number of ribs and stringers divide the wing box into a lot of small boxes. In general, the operator enters the inside of the wing and tightens all the structurally connected parts before the skin panel is attached during the wing box assembly process.

DESIGN PROBLEM & OPPORTUNITY

/ Focused on the operators who work in the wing box

The distance between the two ribs is too narrow for operators to move easily.

He or she needs to kneel to try to get the target at the bottom.

The operator needs a mattress to kneel or lie down to work on the bottom nuts or fasteners.

Non-ergonomic postures in the cramped space lead to neck and waist pain.

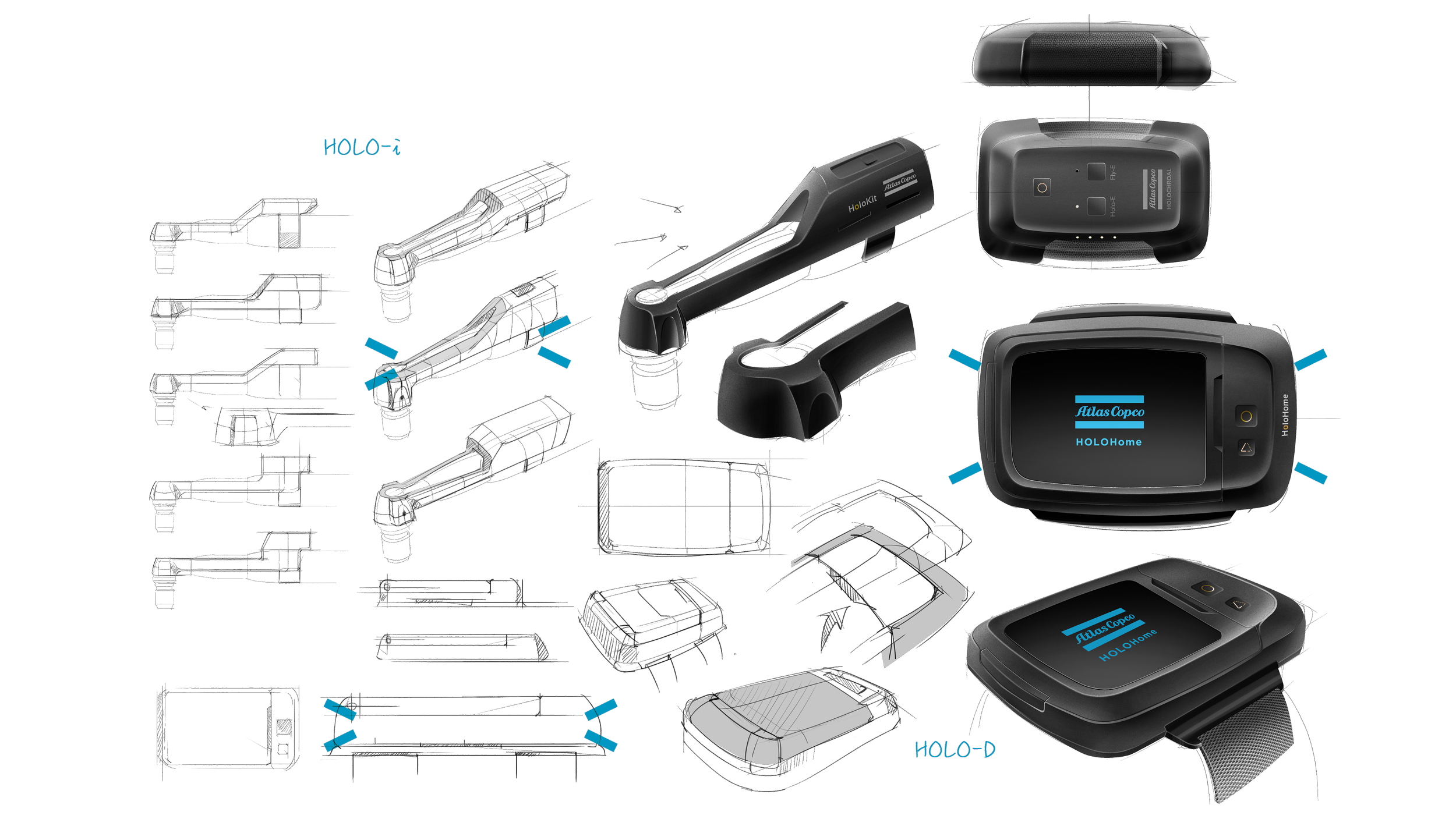

HOLO

" How might we help the operators to see the hidden areas and help to decrease their fatigue during assembly?

Let us deep dive into the “people-centred design”

Exploratory research | Field trip

In the first week, we visited the Airbus Aerospace Assembly Station as a class group in Hamburg, Germany. Then we flew from Hamburg to Stockholm, Sweden, to visit Atlas Copco and had a tools workshop there. After returning to Umeå, we separated into four different groups to summarize and analyze the field studies.

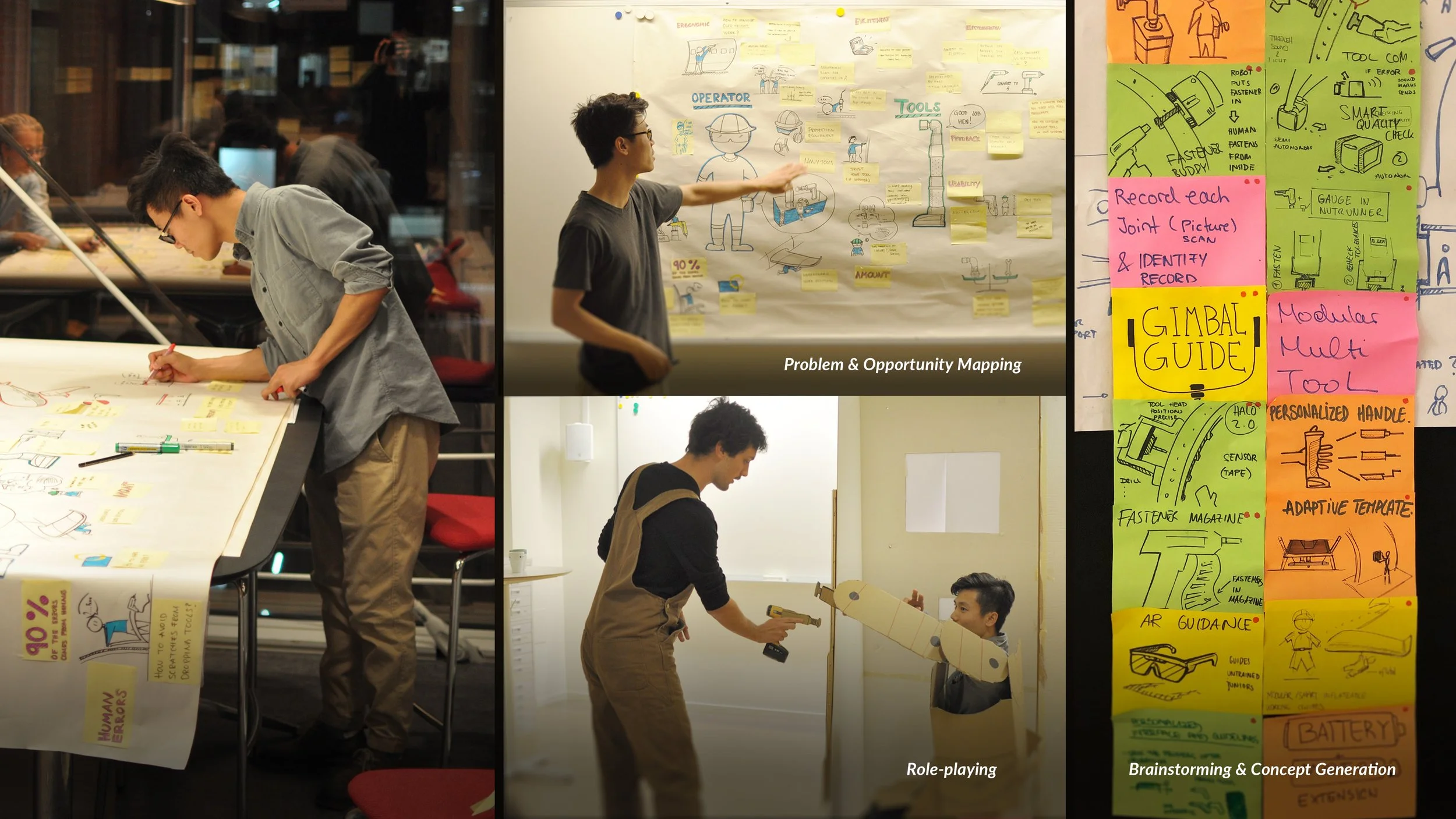

Internal workshop | How to gain an overview of the stakeholders and their contexts?

After the field trip, we started a 3-day internal workshop based on initial studies. Once we identified specific problems or design opportunities, we visualized them and generated our concepts to show how we addressed the aerospace assembly issues.

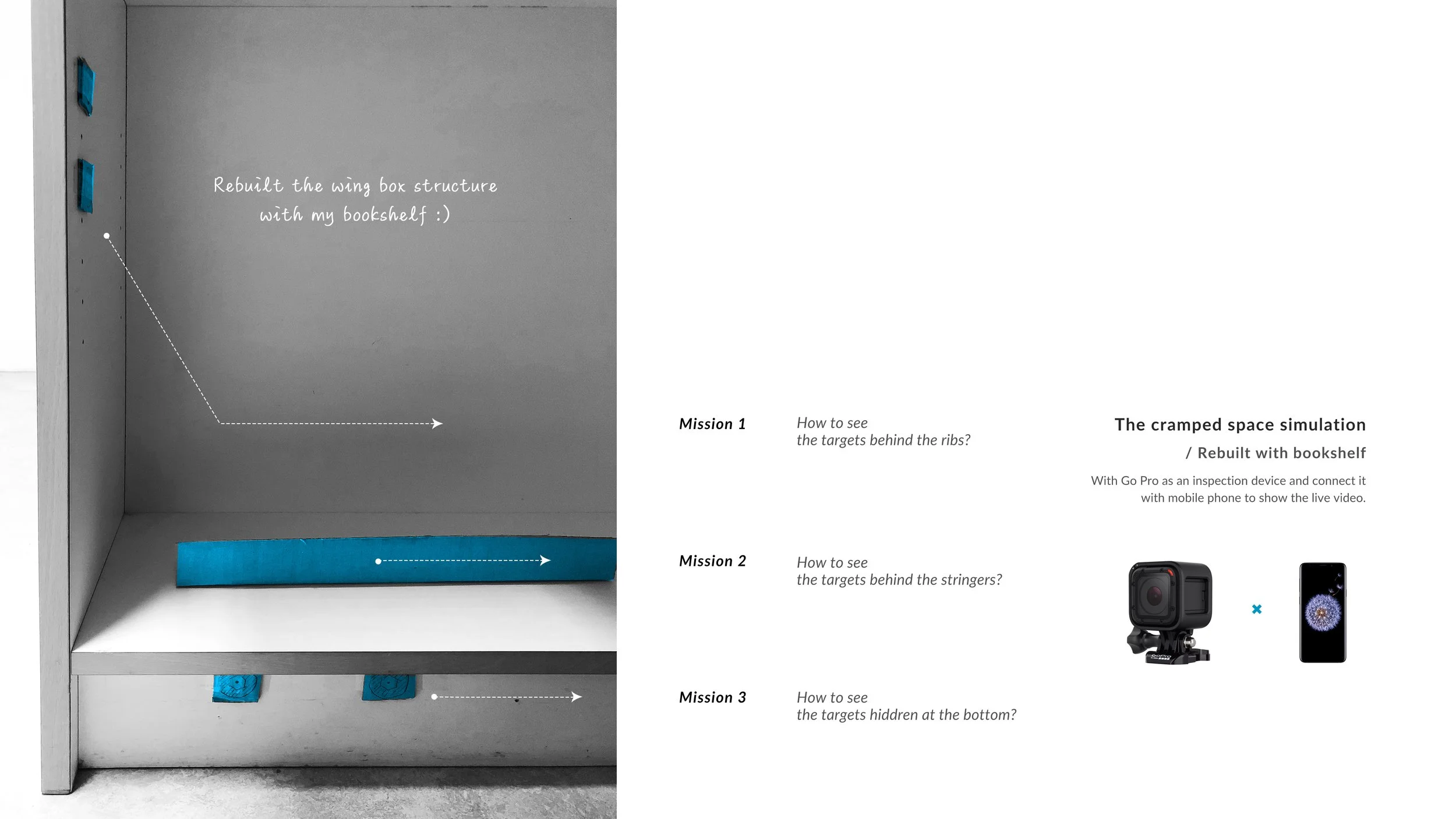

Role-playing | Simulation in compact space

To accurately experience the sensation of working in a confined space, I crawled under my desk to explore the challenges and limitations of this compact area.

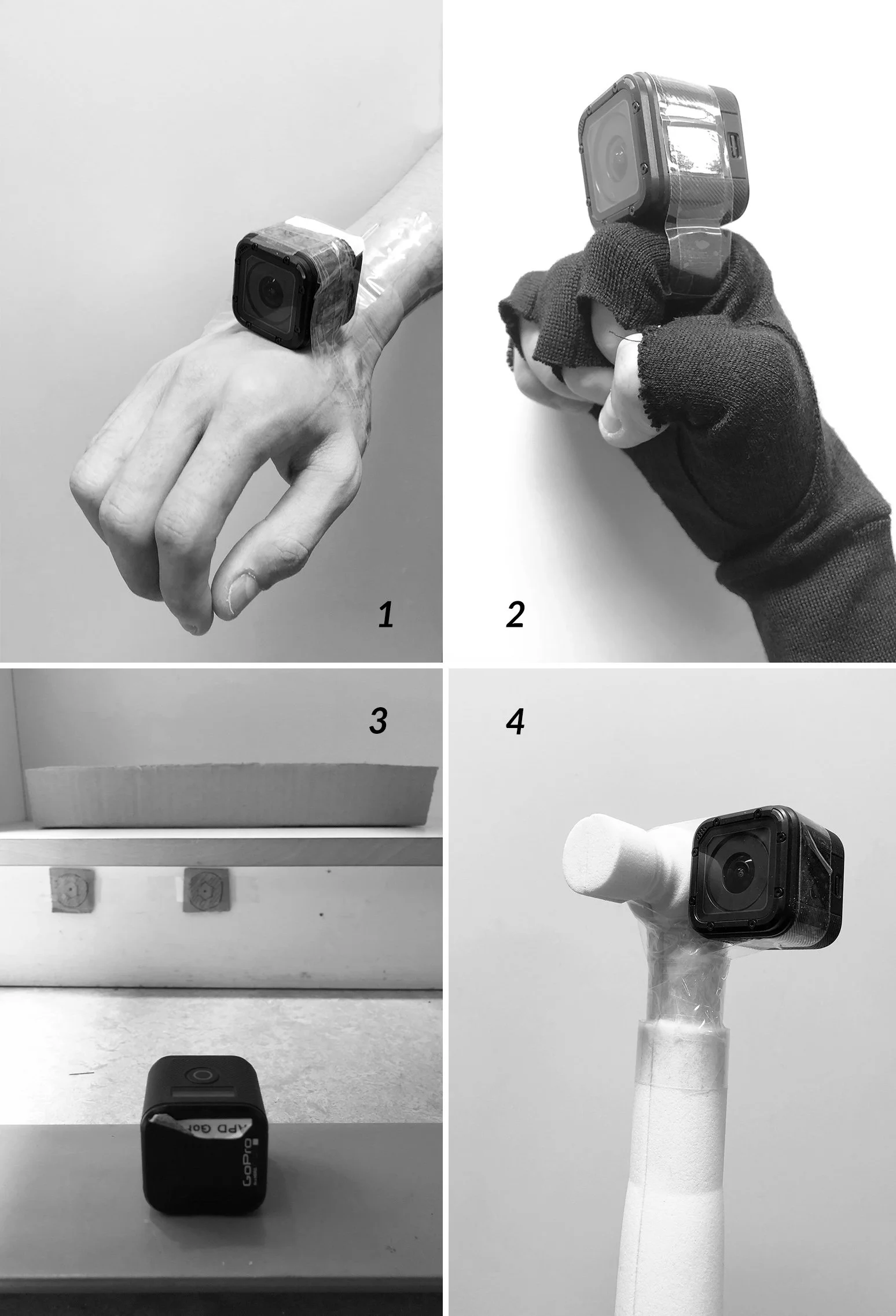

Mock-ups testing

1. A camera on the back of the hand

2. A camera on the index finger

3. Positioning camera

4. A camera on the tool’s head (WORKS BEST)